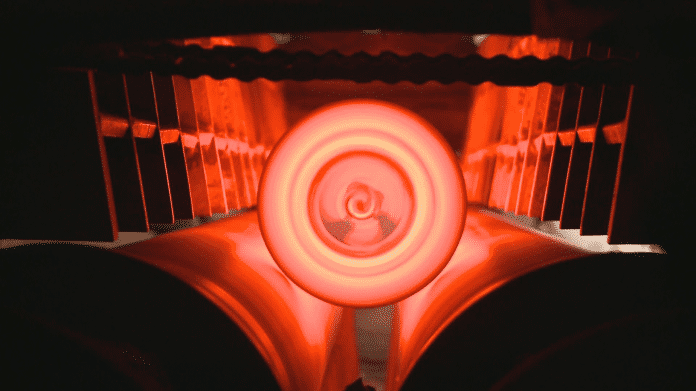

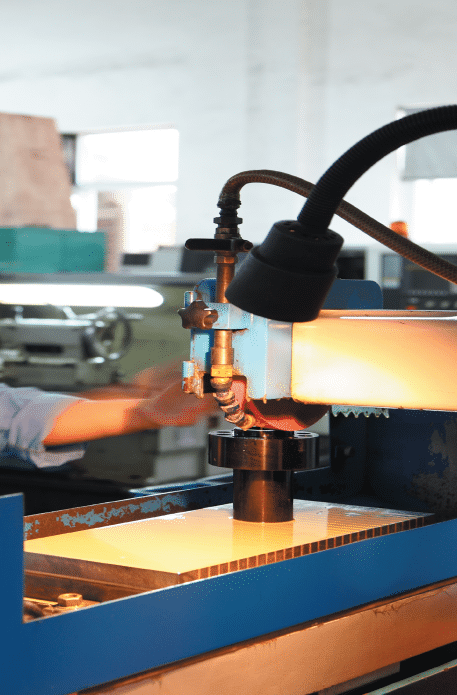

JINYI invested in metallurgical research and this allowed us to offer an exclusive range of bimetallic alloys that solve wear problems. The bimetallic alloys are produced in modern sophisticated centrifugal casting facilities.

- E-mail : [email protected]/[email protected]

- Tel : +86-574-55002386

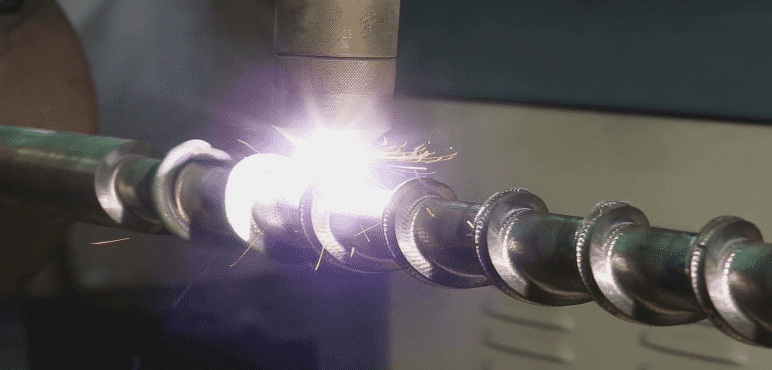

JYS series bimetallic alloys for screws.

JYS series bimetallic alloys for screws.

E-mail :

E-mail :  Tel : +86-574-55002386

Tel : +86-574-55002386

Fax : +86-574-86365887

Fax : +86-574-86365887

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China