- E-mail : [email protected]/[email protected]

- Tel : +86-574-55002386

FOOD PROCESSING AND EXTRUSION

Single and twin screw extrusion is used to process a varity of foods for human and pet consumption. Common extruded foods include sausages, processed meats, dough, pasta, cereals, snack foods, candy and animal feeds. JINYI manufactures monolithic Stainless steel screw barrel sets for ultra pure applications.

Food process extruders for the most part are single or twin screw design. There are various different equipment types and many custom designed machines. Each machine is configured for the specific application. General types include single screw cooking, continuous pasta, dough, pelletizing extruders and co and counter rotating twin screw extruders. It is imperative to use acceptable alloys for the construction of the component surfaces that come into contact with the food materials being processed. The barrel ID surface must be compatible with the feed screw and the material being worked. Of equal importance is resistance to abrasion and corrosion wear. Pitting of the ID surface can cause a stagnation of the material being processed leading to degradation and contamination. Significant abrasion wear can result in foreign elements being present in the end product.

Our food processing screws barrels are in various size with high durability and corrosion resistance.

We use the supreme quality raw material to manufacture food processing screw barrel. The accurate dimensions given by our highly skilled professionals, the superior finish make all our clients happy and satisfied with our delivered products.

|

||

|

||

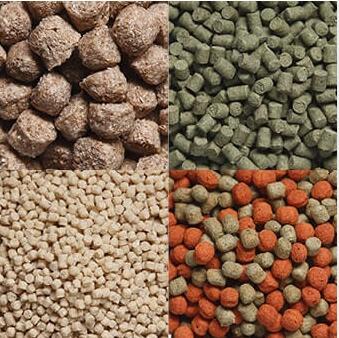

Aquatic feeds Floating, sinking, slow-sinking and specialty products. |

Food Breakfast cereals, pastas, snacks, breads, textured vegetable proteins. |

Pet foods and treats Dry, semi-moist, high meat, co-extruded, multi-colored, novelty shapes. |

Screw

Material: Stainless steel EN1.4404 or SUS316

Available size: D30 - 500mm

Tests: Linearity, Ra-value, thread check, measurements and hardness check

Production process: Raw material check -> Rough turn of both ends -> Full piece drill D30 - > 1.5mm rough turn and leave 1.5mm -> D80 enlarge hole from D65 -> 3mm rough turn shank leaving 3mm -> Clean inside scrap -> Welding the tip -> Fine turning -> 1.5mm rough milling root leaving 1.5mm -> 1st grinding -> 0.3mm half fine milling leave 0.3mm -> 2nd grinding -> 0.1mm fine milling, fly milling root leave 0.1mm -> rough fine polish -> 0.1mm 1st rectify 0.1mm -> vibration 80min -> 0.1mm 2nd rectify 0.1mm -> 3rd grinding -> Drilling shank inside thread -> Key milling -> 0.1mm 3rd rectify 0.1mm -> Fine grinding to required tolerance -> Remove support part -> Drill hole -> Inspection

Barrel

Material: Stainless steel EN1.4542 or 17-4PH

Tests: Measurements and hardness check, linearity, runabout, Ra-value, thread check, pickling paste and salt test

Production process: Raw material check -> Drill D70 -> Stable treatment -> Enlarge to D90 -> CNC rough turn, leave 2.5mm ->Vibration -> Turn boring end -> 1st honing to +0.02/0.05 -> Mandrill testing -> Fine turn to tolerance 0.1mm -> Mandrill testing-> 2nd honing to +0.07/0.10 -> Mill feeding port -> Drill -> Polish -> Inspection

E-mail : [email protected]

E-mail : [email protected] Tel : +86-574-55002386

Tel : +86-574-55002386

Fax : +86-574-86365887

Fax : +86-574-86365887

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China

Copyright © 2020 Ningbo Jinyi Precision Machinery Co., Ltd. All Rights Reserved

Bimetallic Alloys Manufacturers

Custom Bimetallic Alloy Suppliers

Bimetallic Alloys Manufacturers

Custom Bimetallic Alloy Suppliers