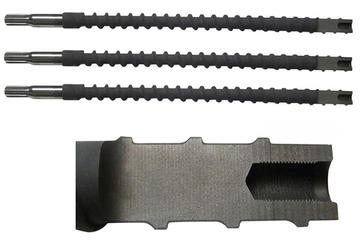

PVD (Physical vapor deposition) is characterized by a process in which the material goes from a condensed phase to a vapor phase and then back to a thin film condensed phase. We are using this technology on our Titanium nitride coated screws.

Advantages

Physical vapour deposition coating is of high hardness and performance, which provide additional protection against abrasion & corrosion.

Application

Suitable for optical products & abrasive plastics processing.

.jpg?imageView2/2/w/360/h/360/format/jpg/q/75)

.jpg?imageView2/2/w/360/h/360/format/jpg/q/75)

E-mail :

E-mail :  Tel : +86-574-55002386

Tel : +86-574-55002386

Fax : +86-574-86365887

Fax : +86-574-86365887

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China

Add : No.158, Qiancheng Rd, Zhenhai, Ningbo City Zhejiang Province, China